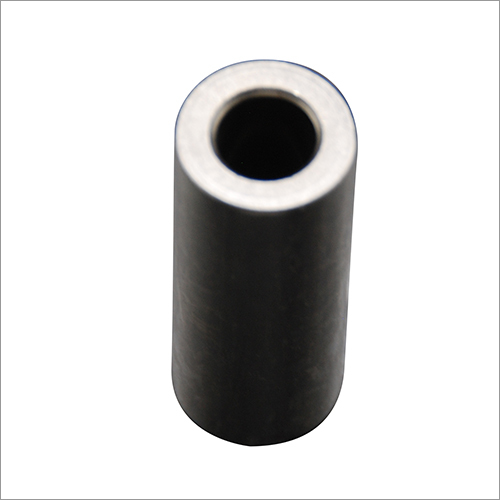

1A021-21310 Piston Pin

Product Details:

- Mount Type Press Fit

- Thickness High Strength

- Engine Type Diesel

- Cooling System Air Cooled

- Finish Type Polished

- Fuel Type Diesel

- Load Capacity Heavy Duty

15.45 USD ($)/Piece

X

1A021-21310 Piston Pin Price And Quantity

- 1 Piece

- 15.45 USD ($)/Piece

1A021-21310 Piston Pin Product Specifications

- Engine Spare Part

- Steel

- Precision Machined, High Wear Resistance

- Engine Connecting Rod Assembly

- Standard

- Approx. 20 mm

- Piston Pin

- Standard

- Air Cooled

- Polished

- Approx. 20 mm (Length) x 55 mm (Dia)

- Alloy Steel

- Heavy Duty

- Diesel

- 0.18 kg

- 1A021-21310

- Diesel

- Press Fit

- High Strength

- Industrial-Grade

- Diesel Engines, Tractors, Construction Machinery

- Standard

1A021-21310 Piston Pin Trade Information

- Shanghai

- Letter of Credit at Sight (Sight L/C), Paypal, Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T)

- 100 Piece Per Week

- 3-5 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Original Kubota package

- All India

Product Description

Piston Pin

KUBOTA began in 1890,which products range from agricultural machinery,construction machinery,industrial engine to water&environment system ect.Kubota is the largest agricultural machiney manufacturer in Japany,the world's leading Mini excavator manufacturer and the world's leading below 100hp industrial engine brand which have compact, lightweight, high-output enjoy a strong reputation in the global market and became many international construction machinery manufacturer OEM engine first provider.

Precision Manufacturing for Superior Performance

Each 1A021-21310 Piston Pin is crafted using advanced forging and precision grinding techniques, resulting in a highly polished and case-hardened surface. This manufacturing process elevates structural strength and ensures minimal wear, even under high-load conditions. The strict 0.01 mm machining tolerance enhances fit and functionality, making it a dependable choice for demanding diesel engine applications.

Versatile Compatibility Across Kubota Engines

This piston pin is specifically designed to fit various Kubota diesel engine models, making it a versatile component for use in tractors, industrial machinery, and construction equipment. Its standard dimensions and press-fit mounting provide straightforward installation and reliable connectivity within engine assemblies.

FAQs of 1A021-21310 Piston Pin:

Q: How is the 1A021-21310 Piston Pin manufactured for high durability?

A: The piston pin is engineered using a combination of forging and precision grinding processes. This creates a robust structure with a high surface hardness due to case hardening, significantly enhancing its durability and wear resistance in rigorous operating environments.Q: What types of engines and machinery are compatible with this piston pin?

A: The 1A021-21310 Piston Pin is compatible with Kubota diesel engine models and is commonly applied in tractors, construction equipment, and other diesel-operated industrial machinery.Q: When should I replace the piston pin in my engine assembly?

A: Piston pins should be replaced when there are signs of excessive wear, noise, or performance decline in the engines connecting rod assembly. Regular inspection is recommended, especially under heavy-duty or continuous-use conditions.Q: Where is this piston pin typically installed within an engine?

A: This piston pin is press-fitted in the engines connecting rod assembly, connecting the piston to the rod to facilitate smooth reciprocating movement within the cylinder.Q: What benefits does the case-hardened and corrosion-resistant surface offer?

A: The case-hardened finish provides exceptional surface strength, reducing wear and deformation over time. The corrosion-resistant polish extends the lifespan of the pin, ensuring stable performance even in harsh operating environments.Q: How does the ISO certification influence the quality of this piston pin?

A: Being ISO certified assures that the piston pin meets international standards for quality, consistency, and safety, providing users with a reliable and proven engine component.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese